Cooperative Transportation by Multiple Mobile Robots with Tools

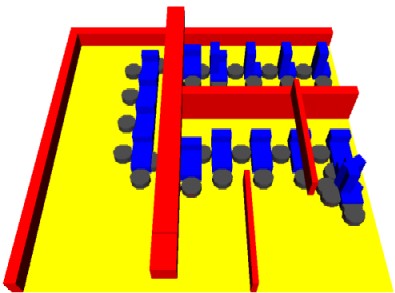

In this research, we proposed a motion planning method that multiple mobile robots transport an object cooperatively in 3D-space. To accomplish this task flexibly, mobile robots use tools. For instance, by using sticks as tools, it becomes easier to put the force of each robot together to an object. When the manipulating tasks are carried out, the stability of operation is improved because the contact area to the object becomes larger. In this study, the important strategies are as follows (see Fig. 1).

(1) Global motion planning

We plan collision-free paths of the object and the robots in 3D-space.

(2) Planning of manipulation

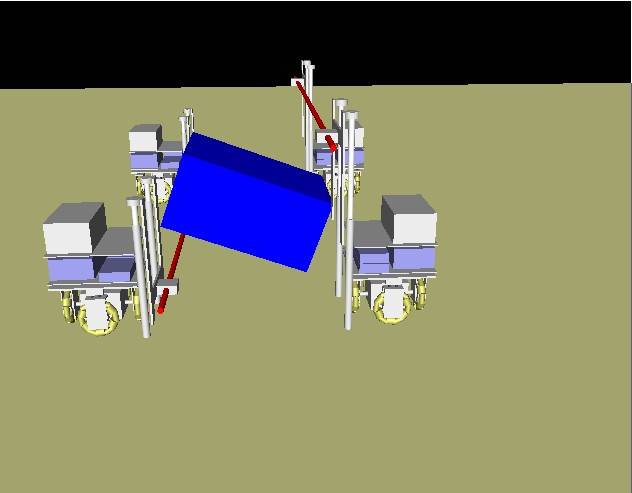

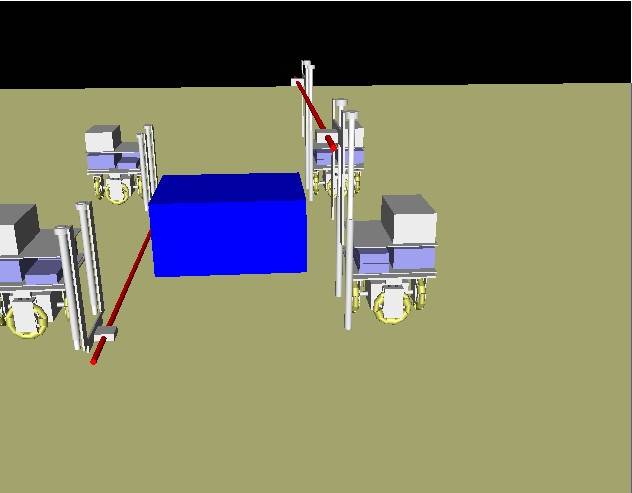

We plan the motion of robots to change the pose of the object.

In (1), an octree is used for representing an object, robots, and obstacles. The paths of the object and robots are searched by using potential function to avoid obstacles. The motion of robots is generated by taking costs of the manipulating the object into consideration. Feasible paths can be found quickly by heuristic search (see Fig. 2).

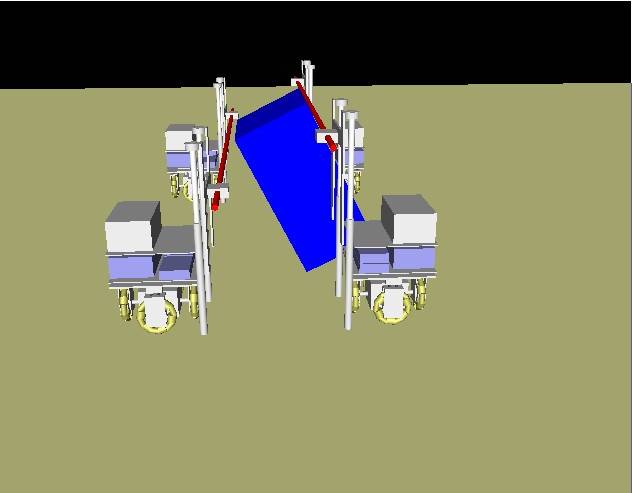

In (2), we construct a method that robots use sticks and manipulate an object to avoid applying excess inner force to the object. We build the manipulation technique suitable for mobile robots by position-control. We propose the manipulation method without using sensor information considering the motion error of mobile robots and the indefinite element of environment from the planning stage (see Fig. 3).

The effectiveness of proposed method was verified by experiments on our mobile robots (see Fig. 4).

Keywords: Tool, Multiple Mobile Robots, Planning, Cooperation

Reference

Fig. 1 Motion planning in 3D-space

Fig. 2 Result of path planning

(a) (b) (c)

(d) (e) (f)

Fig. 3 Result of manipulation planning

Fig. 4 Mobile robot